Today we’d like to introduce you to Emmanuelle Bourlier.

So, before we jump into specific questions about the business, why don’t you give us some details about you and your story.

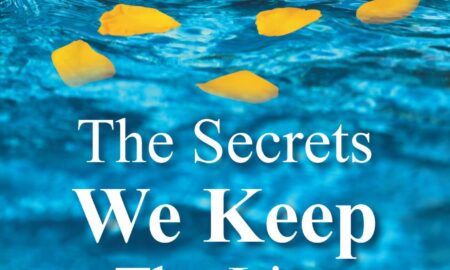

I started the company in 1998 out of my tiny New York apartment while at graduate school for architecture at Columbia University. A friend and classmate invited me to work on a very small but real commission, a 200sf pool house. We designed a translucent garage-type door that pivoted to become a shading canopy.

It needed to be light-transmitting, very stiff and very lightweight. We avidly researched interesting materials. In our research we found that honeycomb is one of the lightest, stiffest structures available, so we looked for a translucent honeycomb panel; to our surprise, there were none on the market.

Finally, a manufacturer in Colorado was willing to produce a mock-up for us. When we saw our first prototype translucent honeycomb panel, it was extraordinary, magical even, despite some glue streaks. It was so lightweight, strong, and the way it manipulated light and views was beautiful. We believed that this new material could have a powerful positive impact on architecture.

The pool house never got built, but we showed our samples to architects and were fortunate when Moneo Brock architects used our panels in a New York loft which landed on the cover of the Spanish edition of Interior Design magazine. Word was getting out and our second clients were Diller Scofidio (now Diller Scofidio Renfro,) who were already “starchitects.”

When we heard their message on my answering machine (this was 1998) we decided to incorporate a company and file for a patent. For about a year while I was still in school, we ran the company out of my apartment, with just an iMac computer, a printer, a fax and a landline with an answering machine. We worked with manufacturers to improve the product and expand the range, we packed up hundreds of sample boxes to send to architects’ offices, and we took the subway all over New York to make product presentations.

When I graduated from Columbia in 1999, I moved to Los Angeles, and we maintained offices in both cities. We worked on material research for Office for Metropolitan Architecture, for their Prada and Illinois Institute of Technology buildings. We developed two new product lines, a cast resin panel which was used at Prada and a honeycomb insulating glass unit which was used for the first time at IIT.

In LA we had a lot of space for experimenting. We made tests for the cast panels on our balcony, then eventually got a small industrial shed space where we produced them ourselves, then moved to a much larger industrial shed, 20,000sf. We continued in house production until the downturn in 2008.

Today in our interior and exterior product lines and in our R&D efforts we focus on sustainability, the well-being of building occupants and the Net Zero Energy goals that are increasingly critical to the building industry. Ironically, we were woman-led and focused on green/environmentally responsible materials long before those things became as significant as they are today.

We’re always bombarded by how great it is to pursue your passion, etc. – but we’ve spoken with enough people to know that it’s not always easy. Overall, would you say things have been easy for you?

Not a smooth road! Struggle is part of the process, it’s how you learn, improve, gain experience. Some challenges come from the outside. We have been through two economic downturns, in 2001, we lost half our pipeline in the dot com crash and in 2008 again sales plummeted as the building industry reeled from the recession.

In both cases, we had to make difficult decisions, streamline our operations and our product offerings. There were scary moments. When my son was born in 2009 we were still scrambling hard to recover; I remember walks with him in a baby carrier while I talked on the phone to advisors, clients, vendors, working from all angles to pull the company through.

Then there are the challenges that we set for ourselves. In 2001, we decided to manufacture one of our product lines in-house, gaining valuable experience in the process, though eventually, we went back to outsourcing. Developing new materials is a challenge we embrace, we know that all the initial failures will make the end product stronger.

And as a team, we like to challenge ourselves to learn continuously both inside and outside the office. I started skateboarding (bowl-riding) with my 9-year-old son about five months ago. There are beautiful parallels to entrepreneurship. You get comfortable with trying and failing/falling, and learning from it. You become a better risk-taker.

Major goals can be achieved – whether adding a new product line, or a skate run that seems daunting – by breaking the process down into steps. Skating has made me a more decisive and agile leader.

So, as you know, we’re impressed with Panelite – tell our readers more, for example, what you’re most proud of as a company and what sets you apart from others.

We have always specialized in the application of honeycomb technology to architectural building products. We were the first to develop a translucent honeycomb panel in 1998, and since then we have developed a full range for interiors and exteriors.

We are known for materials that are both beautiful and high performance. We won’t produce a material that isn’t aesthetically compelling. Nor would we make a material that is purely decorative; there must be a strong performance factor. Our expertise being in honeycomb, our products are high-performance both structurally and environmentally.

Our interior grade honeycomb panels are 80% air, meaning they use a fraction of the raw materials of a cast resin, acrylic or glass sheet, and their light weight and stiffness saves time and materials in installation. Our honeycomb glass unit for exteriors offers amazing energy savings. The honeycomb shades from solar heat and diffuses daylight, so you reduce your cooling costs and your lighting costs.

Just as importantly, user well-being is much higher in a space that is amply daylit than in a space with shades or tinted glass. What sets our product apart is our commitment to innovation, environmental sustainability, and quality. What sets our service apart is the fact that the company was founded by architects; we have a deep love for the practice and understanding of our clients’ priorities, a strong attention to detail.

As a company, we are collaborative, resilient, fiercely positive, and we maintain a sense of humor in the toughest of times. Many of our employees have been with us for more than ten years.

So, what’s next? Any big plans?

We have many exciting plans for the future, including new product lines and groundbreaking technology geared towards Net Zero Energy goals.

We are also excited to grow our team and to build out a new showroom and lab space in LA. Other plans I can’t freely discuss yet…

Pricing:

- Interior panels range from $800-$1500 each

- Exterior honeycomb glass unit pricing depends on unit makeup and quantity, range is $28-65/sf

Contact Info:

- Website: www.panelite.us

- Phone: 323-297-0115

- Email: [email protected]

- Instagram: @panelite_innovates

- Facebook: https://www.facebook.com/Panelite/

- Twitter: https://twitter.com/panelite_

- Other: https://www.linkedin.com/company/2565062/admin/

![]()

Image Credit:

Image Credit:

- Panelite TTWR3 panels

- Garmin HQ, Gould Evans Architects, Roger Reed Photo

- Emmanuelle + Nicolas at the Cove skatepark

- Raleigh Union Station, Clearscapes Architects, Dan Nicely Photo

- StoryCorps, MESH and MASdesign Architects, Christopher Weil Photography

- AIA/LA Offices, Clay Holden Architects, Jeff Badger Photography

- Marina Twin Towers, Doha Qatar, E Square Architects + Photo

- Westfield HQ, Woods Bagot Architects, Art Gray Photography

Getting in touch: VoyageLA is built on recommendations from the community; it’s how we uncover hidden gems, so if you know someone who deserves recognition please let us know here.

Carlson Hatton

February 22, 2019 at 18:55

Really inspirational Emmanuelle! Such a unique product and combination of aesthetics and functionality. I have some Panelite sliding doors in my house that always get compliments from visitors. Thanks for sharing!

Emmanuelle Bourlier

July 31, 2019 at 20:10

Thank you so much Carlson! So happy you love your sliding doors. We are huge fans of your work as you know. 🙂