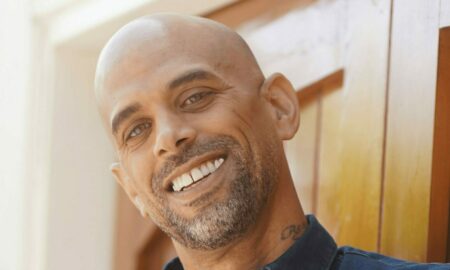

Today we’d like to introduce you to Carlo Ballatori.

Today we’d like to introduce you to Carlo Ballatori.

Carlo, please share your story with us. How did you get to where you are today?

Bandel Mfg., Inc. was started 70 years ago as a metal stamping shop which catered to customers who were seeking “short-run” jobs rather than running millions of parts. We have expanded our capabilities of the years to supply a wide range of metal fabricating techniques including precision metal stamping, tool and die, CNC machining, wire EDM and laser cutting. These days, we still supply short runs but we tend to work on jobs which require hyper precision and detail, while achieving short lead times (mainly aerospace stuff).

I am the planner and sales manager at Bandel. I was brought in to help certify the quality management system to the AS9100 standard, in an effort to expand our business within the aerospace industry.

I met the owner Ed Finley at his favorite restaurant, the Tam O’Shanter where I worked as a waiter. Together, we’ve built a highly talented team which can meet the most stringent of customer demands.

Great, so let’s dig a little deeper into the story – has it been an easy path overall and if not, what were the challenges you’ve had to overcome?

The business has gone through many ups and downs. As a small business, we are highly dependent on very few large customers. Business has been great the past few years, however, I’ve been told that there are some scary financial stretches that owner Ed Finley has had to wait out.

In addition, it’s been difficult to change over the quality management system to meet the requirements of the AS9100 standard. We are a small shop and the changes mainly impacted the expectations on paperwork and documentation. Many of our employees have been here a long time and changing the culture and their work practices of the company has been a long and onerous road.

Bandel Manufacturing – what should we know? What do you guys do best? What sets you apart from the competition?

We specialize in precision metal stamping, machining, laser cutting and wire EDM. We perform full metal fabrication and can meet the most stringent customer requirements. We have a highly talented and dedicated team which can turn around the most difficult projects in the shortest times imaginable. This has translated into significant demand from the aerospace industry, in addition to growth in offering some state of the art metal fabrication equipment.

What has been the proudest moment of your career so far?

The proudest moment of my career was achieving the AS9100 accreditation. Coming in and knowing little about the business, this was a monumental task. We just recently passed our fifth consecutive successful audit to retain our accreditation.

Contact Info:

- Address: Bandel Mfg, Inc.

4459 Alger St.

Los Angeles, CA 90039 - Website: www.bandel.com

- Phone: 818-246-7493

- Email: [email protected]

Image Credit:

Carlo Ballatori

Ryan Horlacher

Getting in touch: VoyageLA is built on recommendations from the community; it’s how we uncover hidden gems, so if you know someone who deserves recognition please let us know here.