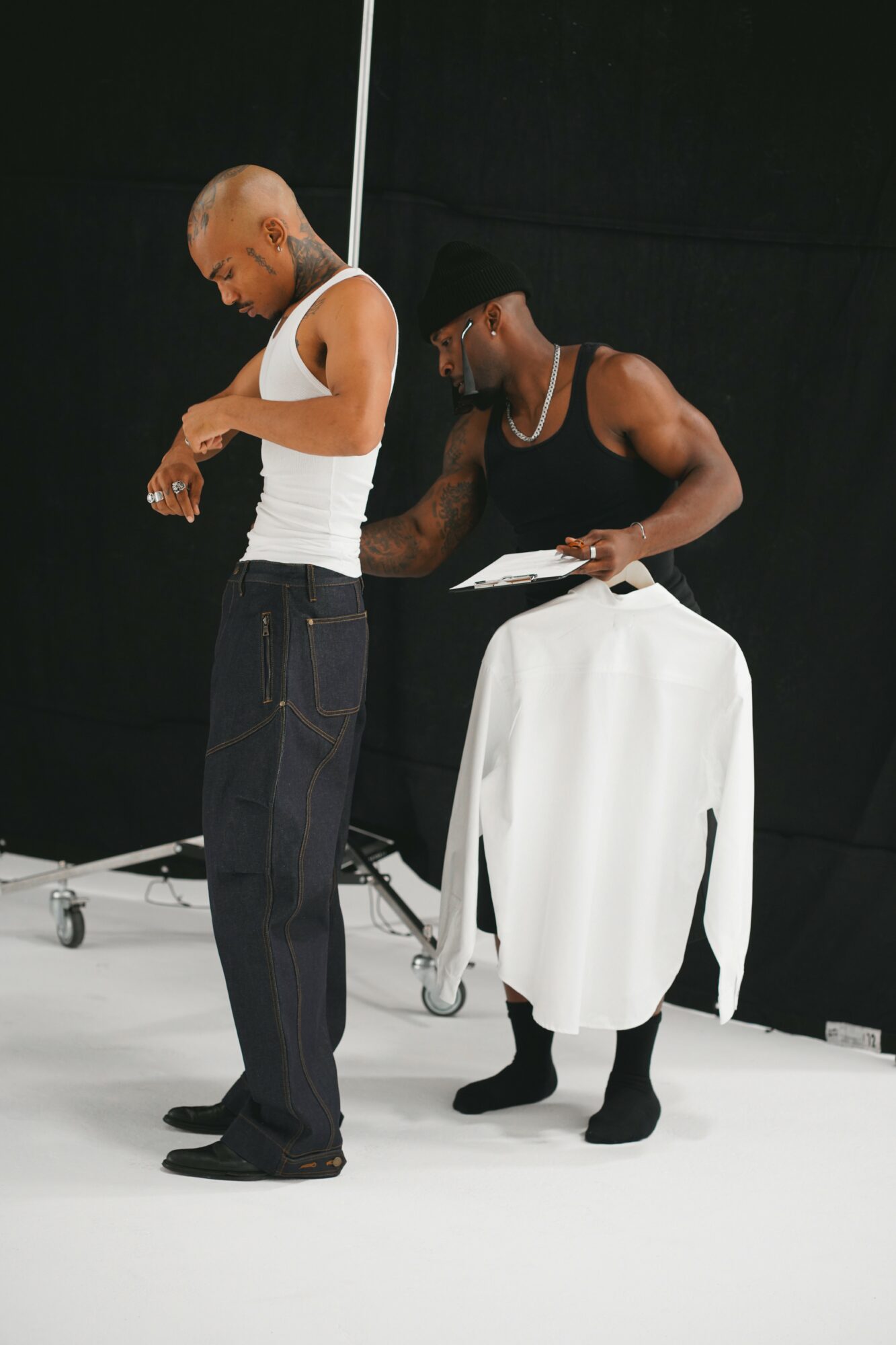

Today we’d like to introduce you to Branden Mitch.

Hi Branden, can you start by introducing yourself? We’d love to learn more about how you got to where you are today?

I got my start thrifting. Every week I’d hit different thrift stores and flea markets—Melrose Trading Post was basically my classroom. Every Sunday I was there studying pieces, learning washes, stitching, quality, and fit. I realized I was drawn to vintage because the craftsmanship was different—stronger materials, better cuts. Meanwhile, most modern brands felt cheap and synthetic.

That’s when I started paying attention to fit. I’d own five pairs of black sweats, and each one fit differently. I kept thinking, there has to be a better way. That curiosity is what pulled me into silhouettes and made me obsessive about how things were cut.

When I finally decided to start my brand, I was intimidated. I didn’t know anyone in manufacturing, especially in LA, so I started small with blanks—buying hats, embroidering them, and seeing if I could even move product.

One day at the flea market, a vendor connected me with my first manufacturer. I had no real experience, just ideas and a willingness to learn. My first cut-and-sew piece was a sweatsuit. It actually came out solid, but I never released it. I didn’t feel ready, and LA manufacturing isn’t cheap. I thought about manufacturing in China but I wanted to stay local, be fully hands-on, and understand the process before I committed to a real production run.

Then life started life’n, so I taught myself how to sew. It felt like the only way I could achieve the silhouette I had in my head without paying LA sample prices.

I locked in. Started by repurposing thrifted clothes, experimenting until I understood structure and proportion. Within six months, I developed my first base silhouette—the one that became the foundation for my denim and sweats.

I’m sure it wasn’t obstacle-free, but would you say the journey has been fairly smooth so far?

It hasn’t been a smooth road, but I’ve learned a lot. The biggest lesson is to pace yourself. When you’re starting out, you want everything to move fast, but in manufacturing—especially when you’re building from scratch—delays are part of the process. You have to give yourself grace.

Another key lesson is to check every invoice and double-check every detail. Manufacturing in LA is expensive, and one mistake can set you back. I also learned that not every manufacturer understands silhouettes the way you see them, and that realization is what pushed me to teach myself how to sew.

It’s taken me over three years to reach a point where I finally feel real momentum. It’s not easy, but every challenge has been worth it.

Appreciate you sharing that. What else should we know about what you do?

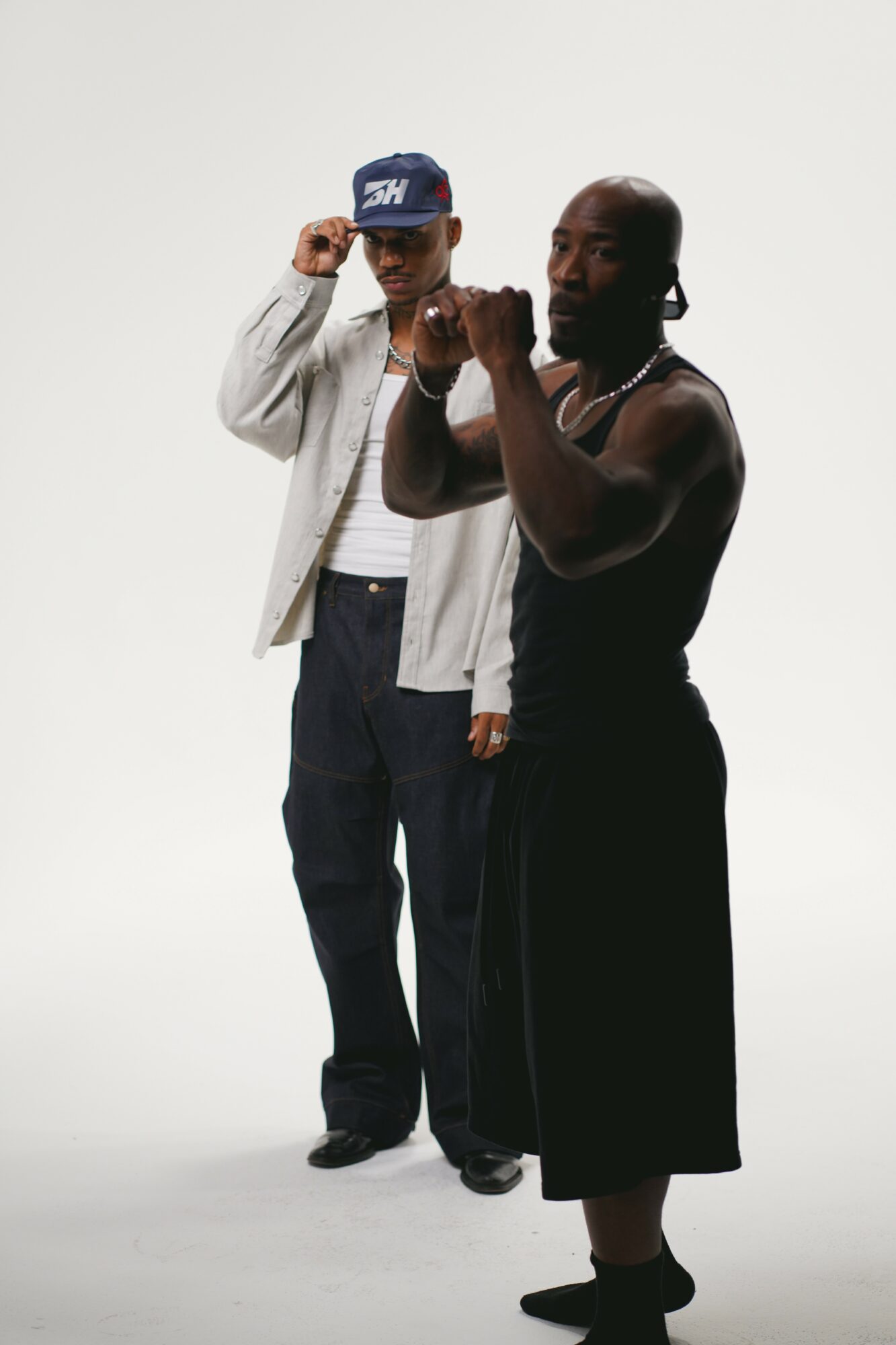

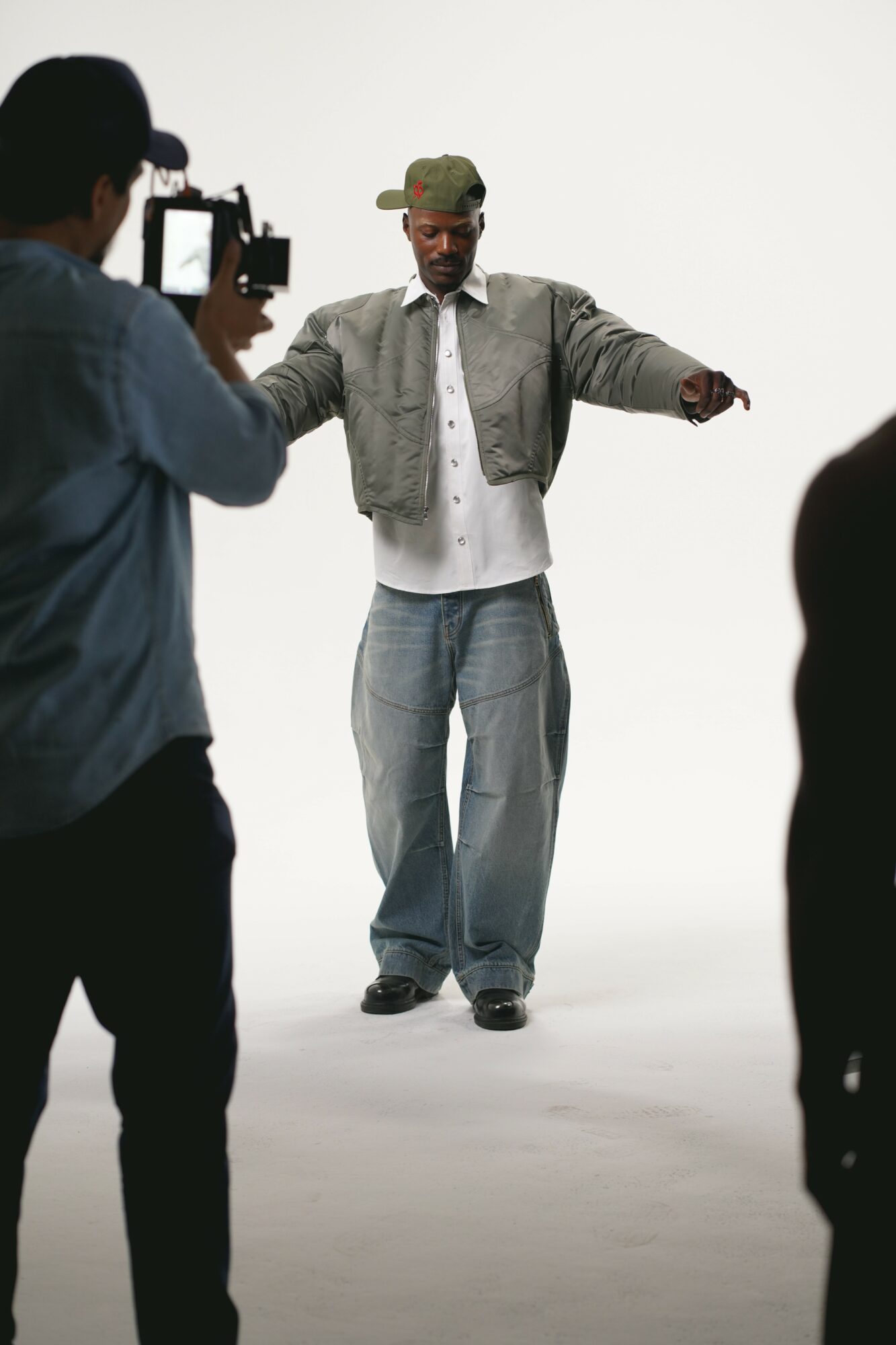

I design and produce all my pieces in Los Angeles under BAD HACHI STUDIOS, and I’m best known for my silhouettes—especially my denim.

I focus on menswear, but I create a range of pieces: pants, sweats, shirts, and a few accessories.

My denim is what I’m most proud of. I taught myself how to sew just to perfect that fit. I don’t know too many people—designers included—who will teach themselves how to sew just to get the right fit for their clients. And this is coming from someone who had zero sewing or pattern-making experience. No manufacturer could capture the shape I wanted, so I figured it out myself. The structure, the way it breaks in, and the way it photographs—that’s what makes it stand out.

What sets me apart is my attention to detail and my commitment to quality. Everything is made with top-tier materials—100% cotton or premium denin. Whenever possible, we use deadstock fabrics to do our part in addressing the fashion environmental crisis. We pre-wash select pieces to avoid shrinkage and to ensure the garment fits the same way it did when you first bought it, giving them that broken-in, elevated feel. Every detail is intentional.

What do you like and dislike about the city?

What I love most about Los Angeles is that you can find just about everything you need downtown if you know where to look. It’s all pretty centralized, so you’re not driving all over the city hunting down manufacturing resources. Now, on the flip side, what I like least is the cost of living and production here—LA isn’t cheap! But I’m committed to giving back to my community, which is exactly why I keep my manufacturing local. It lets me infuse genuine LA culture into my line and support the area I live in.

Contact Info:

- Website: http://badhachi.com

- Instagram: https://www.instagram.com/brandenmitch/?hl=en

Image Credits

images shot by: Jamal Akil